E- בריוו פֿאָרמאַט טעות

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

נייַעס

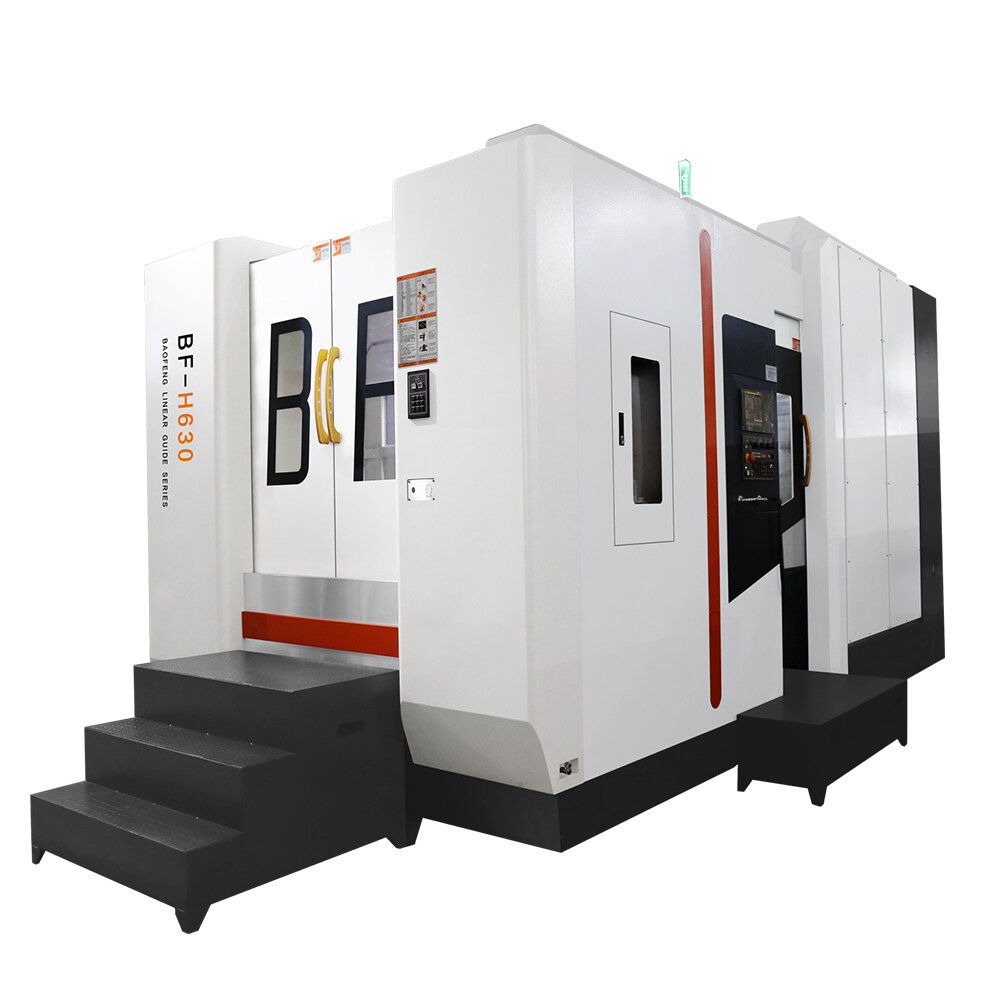

How many Aspects does the Earthquake Resistance of CNC Horizontal Machining Center have?

For the CNC horizontal machining center, it is necessary to take preventive measures to prevent electric shock and electrical accidents caused by the high voltage in the main electrical cabinet, control panel, transformer, motor, terminal box, or operation panel and its area during the operation. At the same time, it is also necessary to pay attention not to touch the switch of the machine tool with wet hands to prevent electric shock. It needs to be checked once a quarter to prevent the line from aging or some machine tool function errors, to prevent accidents from happening in the future, and control the occurrence of accidents from the source.

At the same time, prepare a solid workbench around the machine tool, and do not slide its surface. Only by carrying out the inspection correctly, and then operating according to the operation manual in the process of operation, can the machine tool operate better and prolong its working life of the machine tool.

The CNC horizontal machining center should be far away from the vibration source and should avoid the influence of direct sunlight and thermal radiation, as well as the influence of humidity and airflow. If there is a vibration source near the NC machine tool, anti-vibration grooves should be set around the machining center. Otherwise, it will directly affect the machining accuracy and stability of the CNC machine tool and will cause poor contact and failure of electronic components, which will affect the reliability of the machining center.

The vibration resistance of the CNC horizontal machining center refers to the ability of the machine tool to resist deformation under alternating load, also known as dynamic stiffness, which represents the dynamic performance of the machining center. It includes the ability to resist forced vibration and the ability to resist self-excited vibration. The former is customarily called vibration resistance, and the latter is usually called cutting stability.

- Forced vibration. The sources of forced vibration are a dynamic unbalanced force of high-speed rotating parts, reversing impact force of reciprocating parts, cutting force of periodic transformation, etc. The external vibration source of the machine tool is transmitted to the machining center through the foundation, which can also produce forced vibration. When the frequency of the vibration source coincides with the resonant frequency of a certain vibration mode (such as bending vibration and torsional vibration) of a certain part of the machining center (such as the bed and headstock), common vibration will occur, which will greatly increase the amplitude and even force the cutting to be impossible.

- Self-excited vibration. Self-excited vibration is a relative vibration between the tool and the workpiece. It occurs in the cutting process and is generated by the interaction between the cutting process and the dynamic characteristics of the machine tool structure. Its frequency is similar to the natural frequency of the machining center system. In general, the self-excited vibration will intensify with the increase of the cutting force. The larger the cutting force, the more intense the self-excited vibration, but the cutting process stops, Vibration also disappears, so the ability to resist self-excited vibration also becomes cutting stability.