E- בריוו פֿאָרמאַט טעות

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

נייַעס

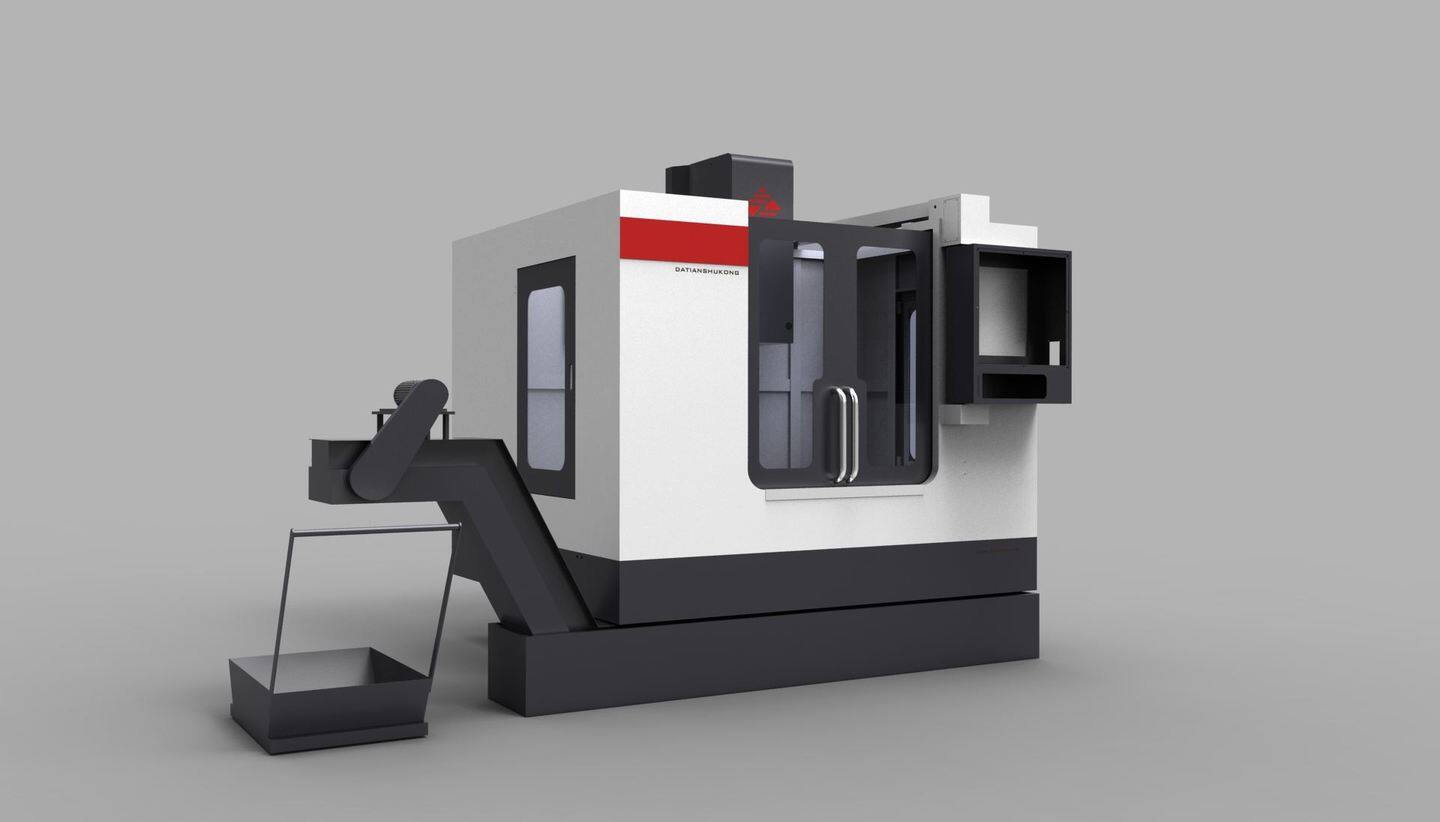

How much do You Know about CNC Machining Process of Precision Parts?

The outer surface of precision parts CNC processing products with high-quality standards is divided into production and processing links, which can usually be divided into rough machining, semi-precision milling, and precision milling.

We divide the CNC machining of precision parts into the following four links:

- Face before the hole

For the shell, bracket, connecting rod and other parts, CNC machining of parallel surfaces should be carried out before CNC machining of holes. In this way, the production and processing holes can be accurately positioned on the parallel plane, ensuring the position accuracy of the parallel plane and the holes, and providing convenience for the production and processing of the holes on the parallel plane.

- CNC machining datum first

In the production process of parts and components, the outer surface serving as the reference for accurate positioning should be processed by CNC first, which is convenient and better to provide a precise reference for the production and processing of the following steps. It is called "benchmark first".

- Finish CNC machining

The finish CNC processing of the main outer surface (such as grinding and polishing, honing, fine grinding \ rolling production processing, etc.) should be carried out at the end of the processing process planning. The roughness of the outer surface after production and processing is more than ra0.9um, and a slight impact will damage the outer surface. Generally, protective measures need to be taken with velvet cloth. Hands or other objects must be prohibited from directly contacting the product workpiece to prevent finishing the outer surface of production and processing, Damage due to transportation, and assembly between steps.

- Distinguish production and processing links

The outer surface of precision parts CNC processing products with high-quality standards is divided into production and processing links, which can usually be divided into rough machining, semi-precision milling, and precision milling. Mainly to ensure the quality of production and processing products; It is beneficial to the rational use of machinery and equipment; Convenient and reasonable arrangement of heat treatment process steps; It is also convenient to detect hair embryo defects as soon as possible.

What are the characteristics of CNC machining of precision parts?

First, CNC precision parts processing is more efficient. The machining of CNC parts can process multiple surfaces at the same time. Compared with ordinary lathe processing, it can save a lot of processes and time, and the quality of parts processed by CNC is much more stable than an ordinary lathe.

CNC precision parts processing plays an irreplaceable role in the development of new products. Generally speaking, parts with different degrees of complexity can be processed by programming. Modifying and updating the design only requires changing the program of the lathe. Greatly shorten the product development cycle.

The automation degree of CNC precision parts processing is very sufficient, which greatly reduces the physical labor intensity of workers. Workers do not need to control the whole process like ordinary lathes in the processing process, but mainly observe and supervise lathes. However, the corresponding CNC processing technology content is higher than that of ordinary lathes, so it requires higher mental labor than ordinary lathes.

Make a purchase of high precision cnc machining, plastic cnc machining near me, high volume cnc machining from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.